Dar Al Arkan completes KSA’s first 3DCP villa

Standing at 9.9m tall, the villa has been constructed using locally made materials including cement, sand, rocks and stones

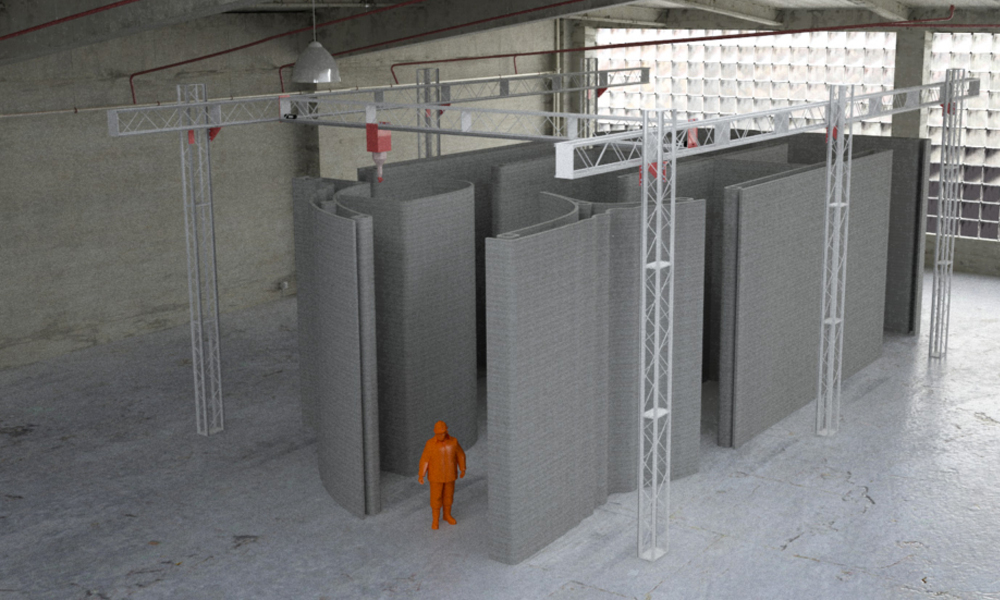

Saudi developer Dar Al Arkan has completed the Kingdom’s first 3D construction printed (3DCP) two-storey villa, within the Shams Al Riyadh residential development.

Standing at 9.9m tall, the villa has been constructed using locally made materials including cement, sand, rocks and stones, with varying degrees of concentration, to ensure that the structure is up to four times stronger than traditional construction.

Following the success of the project, Dar Al Arkan said it is currently building a second villa, with each project taking a month to complete. The first floor of the second villa has been fully completed, the developer added, pointing out that it was finished within eight days.

In December 2021, Oman said it built the world’s largest 3D printed concrete building.

The completed villa was printed directly on site, during the summer, without any cooling equipment or shading, which indicated that the technology is capable of printing homes year-round and in any part of the country, the developer pointed out.

Working in collaboration with COBOD, a global leader in modular 3D construction printers, Dar Al Arkan is the first developer in the Kingdom and the region to introduce COBOD’s 3D Concrete Printer to the real estate market, the company said.

3DCP is a future-forward printer that is capable of printing large scale residential units and will be operated by a 100% Saudi team, it added.

In June 2022, Dubai Municipality launched several technical activities around 3D printing technologies.

Dar Al Arkan said that strict protocols and an evidence-based approach had been followed for the project – including the first villa – so as to ensure that it was constructed safely, in accordance with the Kingdom’s building codes in every aspect.

Wael Al Hagan, Project Manager, 3DCP, Dar Al Arkan, said, “We are currently building the second villa, which will typically take a month to complete, but we’ve already finished the first floor in only eight days. This 3D printed villa has additional insulation layers and features that ensure energy conservation, saving up to 30% in energy consumption. We urge all industry experts to visit us and view the first completed villa and the second under construction for themselves.”

He continued, “Our efforts are focused on developing the Kingdom’s real estate sector by integrating the latest trends and technologies, drawn from global best practices to enhance our industry locally and deliver on the objectives of Vision 2030. The introduction of 3D construction printing enables us to focus on greater flexibility of design, strengthen productivity and achieve higher cost efficiency.”

Late in October 2022, SCIB announced the completion of the first 3D printed house in Borneo.

Ziad El Chaar, Vice President of Dar Al Arkan, added that the technology would become increasingly common in the GCC and MENA regions, with a greater adoption rate likely as the technology improves.

He added that he expects the technology to revolutionise how customers purchase and design their homes in the near future, adding that Dar Al Arkan customers will soon be able to select various building designs and authorize the printing of their homes via a click of a button.