Digital twins show the way towards a net-zero emissions construction sector

The construction sector should look towards digital twins if it wants to fall in line with sustainability goals, says Suhail Arfath, director, Digital Transformation and Innovation at Hloov

At the end of 2020, HH Sheikh Mohammed bin Rashid Al Maktoum, Vice-President and Prime Minister of the UAE and Ruler of Dubai, reiterated the UAE’s commitment towards fighting climate change, calling it the ‘most prominent battle of mankind in the coming decades’.

Sheikh Mohammed’s comments came as the country reaffirmed its national pledges and commitments to reducing carbon emissions by 25 percent before 2030, in line with the Paris Agreement – a pact signed in 2016 with the United Nations Framework Convention on Climate Change, that deals with greenhouse-gas emissions mitigation, adaptation, and finance.

While this commitment towards fighting climate change is admirable, it leaves the local construction industry facing a significant challenge – globally, the sector is regarded as a major polluter, contributing huge amounts of waste and environmental pollution. According to a 2020 Deloitte report, the sector’s greenhouse gas emissions account for 40 percent of global greenhouse gas emissions.

The major contributors to these emissions are the materials used, as well as the heating, cooling, and lighting needed for them to operate, as well as all the associated infrastructure necessary for them to continue running smoothly.

There are several issues around climate change that the construction sector needs to care about, starting with companies being responsible for reducing their carbon emissions to achieve net-zero emissions by 2050. Not only would this bring the industry in line with the goals of the Paris Agreement, which aims to reduce global warming to below 2 degrees Celsius, but it will drive decarbonisation along the entire value chain.

However, in order to achieve these lofty ambitions, there is much work to be done, especially since this is an industry that is not the fastest when it comes to changing practices and adopting new technologies. In fact, a recent report by McKinsey ranked construction as one of the least-digitised industries, above only agriculture and hunting.

Clearly, this must change – if the global construction industry is to adapt to the demands and requirements of the modern era, then advanced technology and the digitalisation of the industry will be a key tool in reaching net zero emissions, particularly through the use of Digital Twins.

How can Digital Twins help achieve net-zero construction?

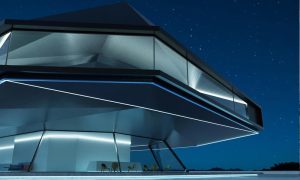

Digital twins are virtual replicas of a physical asset that can be used to simulate scenarios and situations, before the asset is actually built, so as to optimise developments and buildings for peak efficiency and to identify potential issues before they cause a problem.

Industry 4.0 is set to be a key part of developing smart cities and buildings and represents a significant evolutionary shift in manufacturing – which will be a key factor for the construction industry moving forwards. Industry 4.0 centres on the cyber-physical connection, as well as the exchange and automation of data, moving physical assets from being static structures into being part of a connected ecosystem.

Within construction, technologies such as Big Data, the Internet of Things (IoT) and Building Information Modelling (BIM), amongst others, have already significantly improved the way buildings are being designed, built, operated, and maintained.

However, at present, these technologies work in isolation, but certain companies are now starting to marry them to create frameworks for smart cities, where assets, buildings and infrastructure are not only communicating with each other, but actively using the data generated and collected to feed into a Digital Twin model to create an interconnected network, allowing them to become active elements within the energy landscape.

This is possible because the Digital Twin model will allow designers and engineers to develop an understanding of the physics that dictate real world conditions – such as energy flows, environmental conditions, and material attributes. Using machine learning and AI, this data will continuously evolve over the asset’s lifetime, helping to identify patterns in use, where building or network operations aren’t efficient, and help to find solutions to these issues.

Digital Twin, can connect disparate data sources and uses analytics to turn data into actionable insights while fostering collaboration and knowledge-management across an organization, giving organizations the flexibility, and making it versatile to meet challenging needs of carbon neutral infrastructure assets.

Digital Twins present a massive opportunity to the construction sector as it looks to realise zero-carbon goals, promote sustainable, greener building practices, and create communities and cities that are better for everyone to live in.

However, if you thought implementing Building Information Modelling – BIM was hard, then realizing the vision of Digital Twin might look even harder. This is where a well-defined and thought-out framework/approach like the Digital-First framework becomes critical.

The Digital-First approach centres on how you empower your people and leverage data to realise your Digital Twin vision for your projects and organisation efficiently.

A digital-first requires a sea change in thought and approach. It means reconsidering every aspect of a business, from the tools employees use for everyday tasks to a company’s entire organizational structure and governance.

Digital-first does not necessarily mean changing all those things. However, it does mean overcoming the fear of that change and adopting an agile, modern mindset that enables the workforce to innovate and disrupt effectively.

Taking a digital-first approach helps organisations put their people at the centre of the digital transformation and realize a consistent and reliable digital future. It helps define your digital transformation, where you are and where you are going, your business goals, metrics, outcomes, and how to get there most effectively.

Digital-first focuses on the business outcomes you want to achieve and zones in on the technologies that help you leverage and democratise your data and best help you reach them. No technology or tool, no matter how sophisticated and advanced, is a panacea. However, most businesses can benefit from a Digital-First framework anchored by the four principles: Mindset, Skillset, Dataset, and Toolset focused simply on empowering your PEOPLE at the centre.

- Mindset: Cornerstone of Successful Transformation

- Skillset: Thrive as a Digital Enterprise of the future today

- Dataset: Break down data gatekeeping and silos across project Ecosystem

- Toolset: Choose for today’s needs and Tomorrow’s Demands

More than ever, organizations like Hloov, with their team of Engineering & Construction industry experts and technology specialists, and data scientists, are here to help clients realise the value of digital transformation with our carefully designed Digital-First Framework for the E&C sector. Ultimately, assisting clients to reduce waste, costs, and drive growth, providing them with the ability to survive and thrive.