Stronger than steel

Material experts tell Christine Fashugba how the revolutionary non-toxic graphene could change

the construction industry

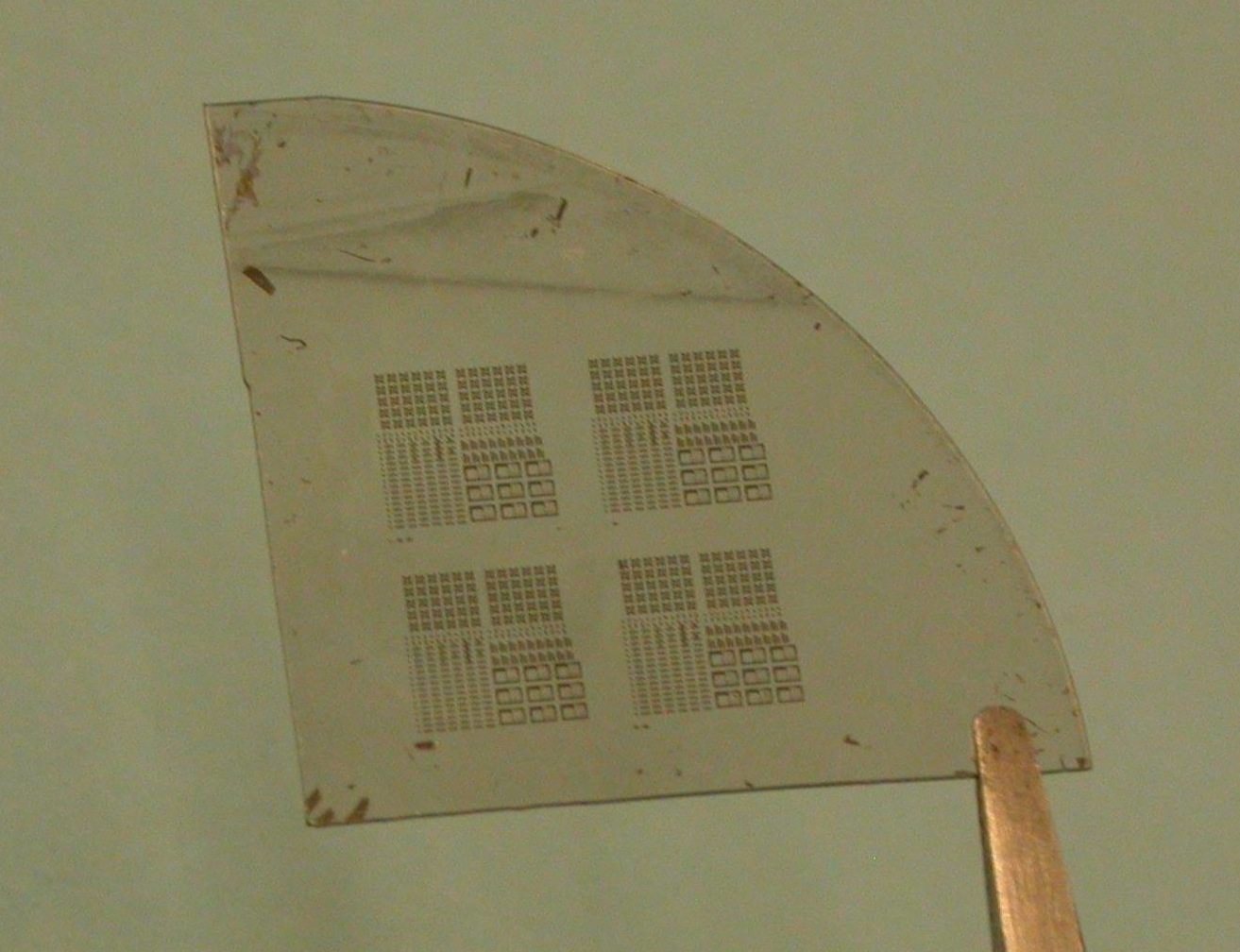

As unlikely as it is an elephant would ever sit on top of a building, potential investors and construction management

in particular may take interest in the fact that it would actually take an elephant “ balanced on a pencil” to break through a clingfilm-thick sheet of the revolutionary material grapheme.

Those were the words of Columbia University’s James Hone, who headed a research project into the material before it

won a Nobel Prize in 2010.

According to Lux Research Inc analyst Alex Carter, despite being in its early stages the non-toxic, 2-dimensional, hexagonal array of sp2-bonded carbon atoms tipped to eventually replace steel, could be a material for largescale

production companies to watch.

Developers are currently investigating the application of graphene for electronics on medical implants due to its high bio-compatibility.

“Graphene is a pure carbon material and is non-toxic to humans and animals. If graphene were to reach large-scale production there would be little issue with its disposal,” Carter says.

“Total lifetime environmental costs in terms of the chemicals necessary to produce graphene nanoplatelets (GNPs) and

the greenhouse emissions related to the energy necessary for graphene production, are still unknown and may not necessarily be an improvement over conventional construction materials, however graphene synthesis and

processing methods are still being invented today,” he adds.

Dr Yu-Ming Lin research staff member Nanometre Scale Science & Technology IBM, dispersed any environmentalists’ concerns regarding the material’s use.

“Graphene is inert and therefore, is not likely to cause negative environmental effects,” she says.

Graphene is mostly known for its strength, which is believed to surpass that of steel, a property which is likely to attract construction industry management. However, Carter asserts it is too early for graphene to have a significant effect on the sector.

“Graphene has not entered into any commercial construction materials yet. The three largest graphene nanoplatelet producers in the US; XG Sciences, Vorbeck Materials and Angstron Materials, also known as Nanotek Instruments, simply do not have the production capacity built up at this stage,” Carter says, adding: “Expect graphene to appear in specialty electronics, energy storage, and automotive composites before moving to even higher volume applications

such as construction.”

Electronics industry leaders Samsung and IBM are already taking advantage of the material’s string of benefits including resistance to erosion from powerful acids and alkalis, the ability to produce faster, cheaper, thinner and

more flexible devices and transparent electronic digital applications.

One of the biggest investors in graphene research, Samsung, has demonstrated a 25-inch flexible touchscreen using the material which has a transistor believed to have limitless speed capability while IBM has created a 150 gigahertz (GHz) transistor.

According to BBC News the quickest comparable silicon device runs at about 40 GHz. Despite the material already creating an impression most notably winning its experimental researchers Andre Geim and Konstantin Novoselov the Nobel Prize in Physics last year much is still being said about its potential including a role a significantly sharper “reading” role in DNA sequencing.

Although Lin’s research mostly focused on electronic applications showing graphene’s mechanical strength property to usually only valid in a microscopic scale i.e. about several microns, because large area graphene generally

consists of patches of small domains or flakes, she believes the use of the material within the construction industry could further develop its properties.

“It remains to be seen how graphene will be used in construction industry as a replacement of steel.

“There are, however, other properties of graphene that may be of interest to the construction industry,” he said.

“Graphene is highly conductive, flexible, and transparent. Therefore, one could imagine mixing graphene into construction materials to enhance its properties,” he concludes.