ZF launches electrified mobile excavator drivetrain pilot project

New 255kg system develops 850Nm of torque and 80kW continuous power with two-speed powershift transmission

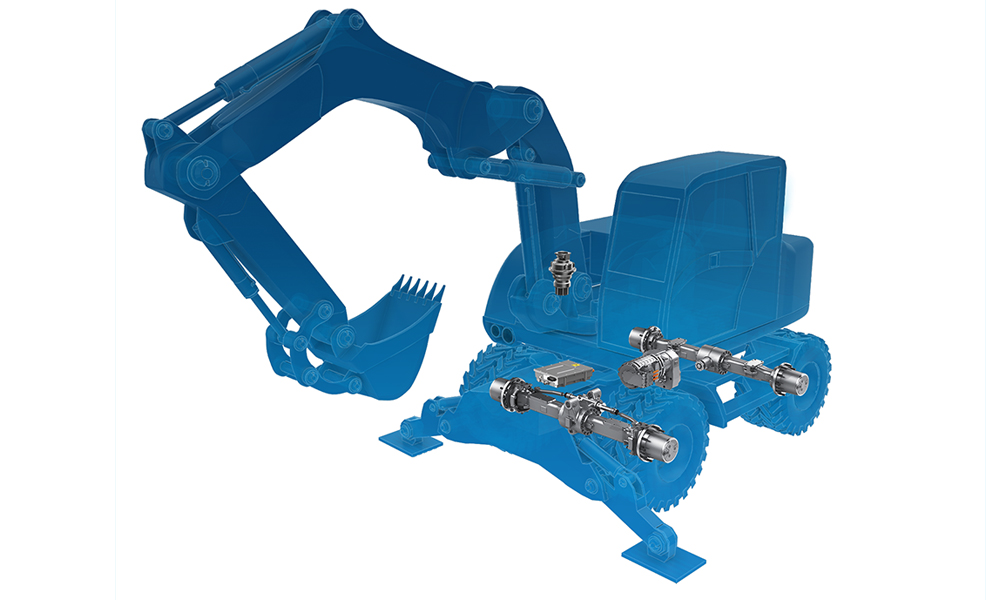

Globally driveline solutions specialist ZF has started its first pilot project for an electrified mobile excavator drivetrain using its newly launched two-speed powershift transmission system, electric motor and inverter.

The company said the system can be scaled up to peak torque 850Nm and continuous power of 80kW. First prototypes have already been delivered to a pilot customer recently and three variants of the electric central drive system – eCD50, eCD70 and eCD90 – are available to cover different vehicle sizes in the targeted applications.

“Shortly after having started volume production of the electrified driveline system eTRAC eCD20 for compact equipment like compact loaders, ZF now can record the next milestone on the road to emission-free construction sites,” said a statement from the company.

“With ZF being the world´s market leader in conventional driveline solutions for mobile excavators, the Group is now extending its product portfolio for this type of construction machinery application by electric drives.”

ZF added that it aims to set new standards for electrical drives, especially when it comes to integrated system solutions. Its product portfolio for mobile excavators is rounded off by a newly developed electrified swing drive and the established MULTISTEER and MULTITRAC front and rear axles.

“The electric drive system satisfies all the expectations for performance and productivity found in traditional drivelines and combines them with the extensive benefits and opportunities that electric systems have to offer. Thanks to its modular design, this new range of electric central drives can easily be adapted for various vehicle applications like backhoe loaders, telehandler, forestry equipment, etc. as well,” said ZF.

The company added that its objectives in developing the system was to create a zero-emissions driveline solution without compromising on performance, with low noise levels, efficient electrical components, robust and reliable mechanical driveline and compact installation space.

The development is In line with the ZF’s “Vision Zero” with the “objective of reducing not only accidents and downtimes, but also emissions to zero”.

The new system under the pilot project has a two-speed transmission mated to an electric motor PSM machine with a voltage of 650V (DC). It weighs a total of 255kg and develops 80kW pf power with a maximum of 100kW and includes features such as SAHR parking brake and optional axle disconnection for both 2WD and 4WD.