Acciona develops platform for monitoring earthmoving operations

Digital tool, compatible with any manufacturer, analyses and controls earthmoving machinery to optimise operations and improve productivity

Acciona has developed a digital earthmoving platform which provides systematic monitoring and control of the machinery used for earthmoving operations, optimising these processes and improving productivity of the projects carried out by the company.

The new tool is compatible with any manufacturer and can be implemented on projects carried out with Acciona’s own machinery or on projects that use subcontracted machinery, said the sustainable solutions infrastructure company in a statement.

Acciona added that the first step in operating this digital platform, which was developed through its Construction Technology Centre, is to compile data from monitoring all of the machinery, which is possible thanks to a GPS system that can be installed simply and non-invasively on each piece of machinery.

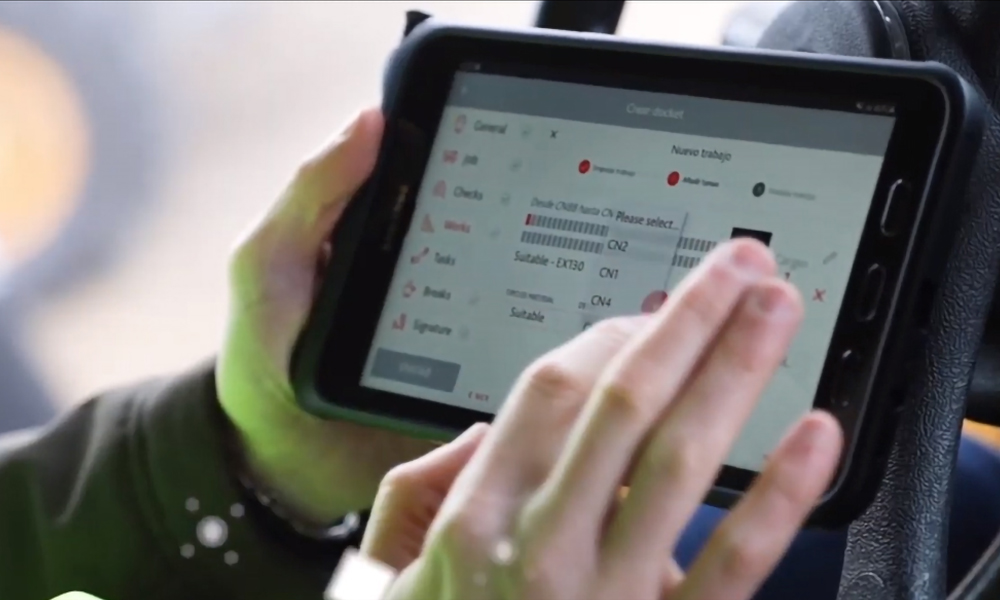

The operator of each machine has the option to enter different operational data using an app and can also record other parameters (consumption, etc.) by installing an additional device, as well as directly extracting data from the machine itself via the manufacturer’s API.

The next step is to process the data collected by the devices. Different events can then be defined using a variety of algorithms, such as the start or end of loading, allowing activities to be identified and performance data to be calculated.

Lastly, the production, time, distance, volume and performance data that has been processed can be analysed and displayed via a web interface. This makes it possible to measure progress and control the operations, as well as to generate regular customised macro reports according to the user’s needs.

José Luis Oliván, project director, Acciona Middle East Construction, said: “By using the earthmoving platform developed by Acciona, users can see all of the assets in real time, including their precise location using positioning maps, as well as the status of each machine. I am sure this innovative tool will be implemented very soon in our coming projects in the region to optimise control of project costs and times, early detection of variations and optimising the machinery use.”

The tool also enables a comprehensive production calculation that shows the duration of different activities, the distances covered and routes used, the volumes excavated or materials moved, as well as many other types of data. This information is represented by graphs and tables for easy understanding.

Acciona added that its use allows analysis of the efficiency of different subcontractors, vehicles or operating zones, as historical data can be processed and presented as performance indicators. Similarly, the platform allows the actual progress of each task to be compared to its initial planning, by displaying the volumes moved using a diagram showing mass.

Other major benefits of this tool include setting up alerts and sending notifications based on productivity thresholds or limits for other user-configured parameters. The platform also stores the historical data for use on future projects to improve a variety of aspects, such as time or cost estimates for certain tasks, or setting performance indicators for subcontractors.

Acciona is already using the platform on one of its most iconic projects – the construction of the Puhoi-Warkworth highway in New Zealand. The platform has also been used on other works, such as in the construction of the Nokian Tyres Technology Centre in Spain, and a section of highway in Font La Figuera.