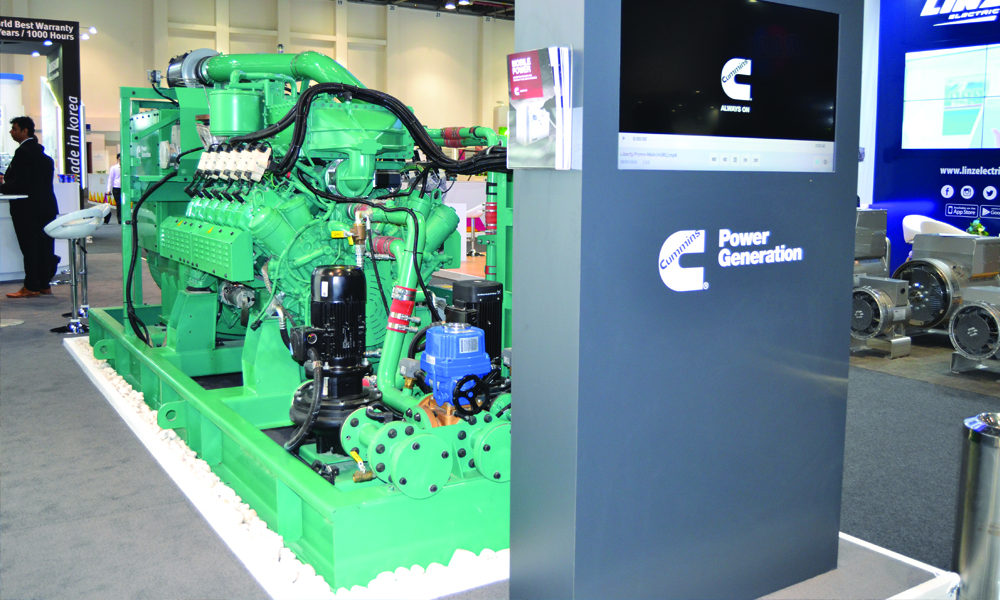

Cummins makes global launch of new natural gas generator series at Middle East Energy

C25G generators offer reduced maintenance costs per kilowatt-hour and are suitable for diverse industrial needs

Global power and engine heavyweight Cummins announced the worldwide launch of its latest gas product, the C25G gas generator series, during the Middle East Energy 2020 show in Dubai yesterday.

Cummins said the C25G series is engineered to deliver superior fuel efficiency with a power density of 500kW (50Hz) and 580kW (60Hz) from a 25l Liebherr G9512 engine, while providing reduced maintenance costs per kWh. The new range is produced in collaboration with Liebherr and has been designed to support any gas power need.

“The new cooperation with Liebherr will enable us to not only serve the market with gensets and offer start-up, commissioning, preventive and corrective maintenance, but also handling of warranty based on the extended Cummins service network worldwide,” said Chris Downs, Cummins Energy Management marketing leader.

The new C25G series offers a total package of gas generator capabilities for combined heat and power (CHP/CCHP), demand-side management and alternative fuel applications, while being suitable for a diverse set of industries ranging from hospitals and manufacturing to commercial buildings and utilities requiring continuous operation whether it is grid parallel or island mode, said Cummins.

“Following the launch of the HSK78G gas generator series, Cummins is now extending its portfolio with the additions of the C25G gas series, offering a wider range of integrated solutions to better serve the needs of our customers across key power nodes,” Downs added.

The C25G models comply with all global emissions regulations while delivering a high electrical efficiency up to 41.6% (50hz) and 40.6% (60Hz) on pipeline natural gas down to 71 and 68 Methane number (MN) respectively at full power.

In addition to its generator capabilities, the control systems of the C25G series provide users with access to advanced monitoring, diagnostic and predictive analytics, maximising the generator’s uptime and reducing maintenance labour costs.

The greater fuel flexibility offered by the C25G series allows users to utilise a wide range of fuels, including pipeline natural gas down to 60MN and low capital BTU fuel offering robust uninterruptable power, anytime.

In addition to the fuel flexibility, the C25G series can minimise the environmental impact with its co-generations capabilities and the NOx emissions offered at as low as 250MN/Nm3 (0.5g/hp-hr), meeting the global product compliance requirements and certifications. Additional benefits linked with the cogeneration offering involve CO2 recovery to be used for heating, cooling or steam generation, while achieving a superior thermal efficiency of up to 46.2% (50hz) and 48% (60Hz) on pipeline natural gas. Alongside these advantages, users can benefit from additional financial savings by selling the excess power back to the national grid.

Similar to the HSK78G series, the C25G models can also run reliably under extreme conditions. The C25G series can deliver full power performance even in ambient temperatures of up to 41C for the 50Hz and up to 34C for the 60Hz models.

“Even though the C25G is not the biggest gas generator of our current gas product range, the benefits of this platform are huge. The significant time and labour-saving features combined with long service intervals offer a unique gas-powered solution with improved uptime and low cost of ownership,” said Downs.

Coupled with the superior reliability and dependability, Cummins offers faster set up due to the pre-installation support and rapid response. Best-on-class after-market capabilities are offered through local account managers, who are supported by a global system of service technicians, engineers and parts distribution centres that are on hands to assist at every stage of the process, from site review to testing and commissioning.

This new collaboration between Cummins and Liebherr is one more example of a long-lasting partnership. For more than three decades, Liebherr has been using Cummins turbochargers. Furthermore, many Liebherr machines, such as material handling and earthmoving machines, as well as mobile cranes, are equipped with Cummins engines that compliment Liebherr’s engine portfolio.