Cat introduces propel drive system for rope shovels

Upgrade for 7495 and 7495 HF models reduces downtime and lowers costs

Caterpillar has developed a propel drive system for its 7495 and 7495 HF Electric Rope Shovels, upgrading the crawler undercarriage for maintenance work that reduces both downtime and cost.

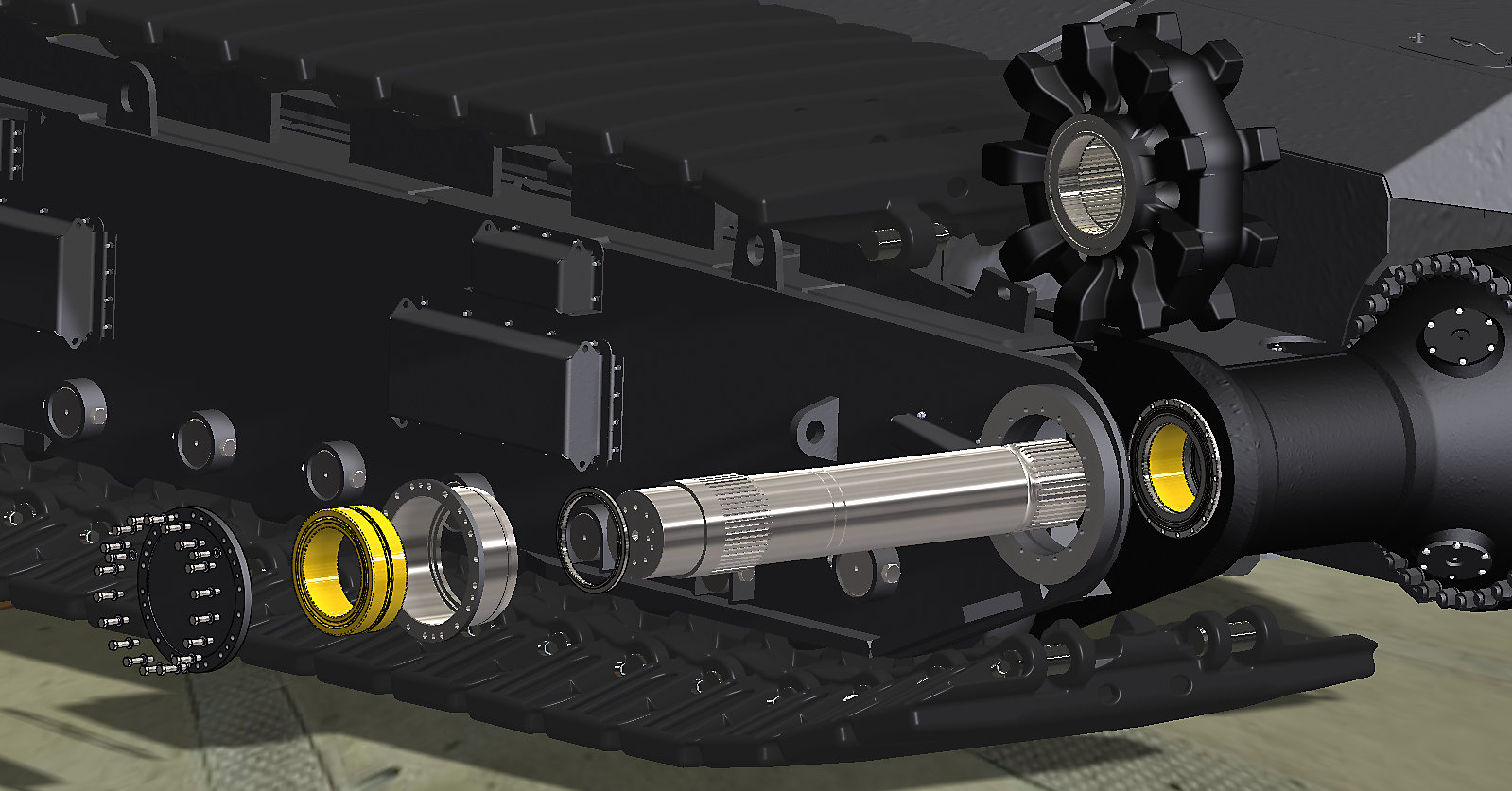

A statement from the construction equipment leader said the propel drive system reconfigures the crawler undercarriage to allow drive shaft and tumbler replacement from the outboard side. This improves access and decreases downtime by days. Improved component design extends durability and increases component life to lower costs even further.

According to Cat, the new design slashes maintenance time and enhances safety by enabling access to drive components without removing the propel transmission. Caterpillar also engineered the upgrade to be a direct replacement in such a way that no machining of the crawler frame is required for installation.

The manufacturer also claims that the new design is robust, with thrust loads evenly distributed on large tapered roller bearings as opposed to bronze thrust plates. The bearings are sealed and continuously purged with fresh grease to keep them free of contaminants, resulting in increased durability in harsh environments and alignment with 25,000-hour planned rebuilds.

Cat has already done field validation of the propel drive system upgrade, operating it successfully for thousands of hours, the statement added.