Voestalpine Schienen introduces rail life-cycle cost system in the region

Track and railway component supplier’s new tool enables evaluation of procurement and maintenance costs for the entire lifetime of a track

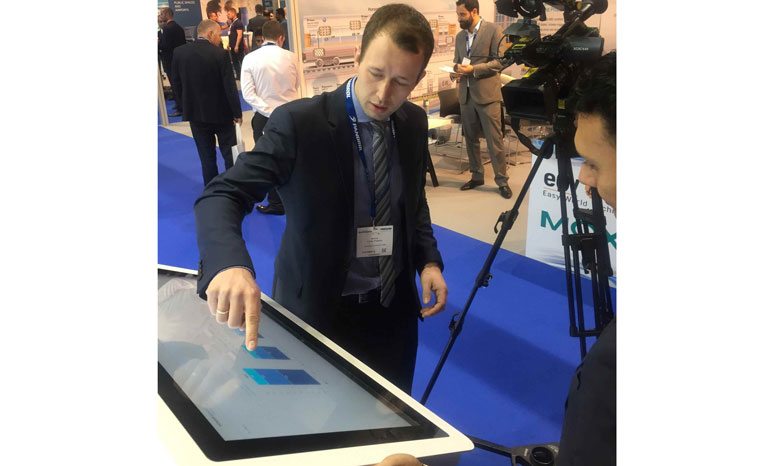

German technology, steel and capital goods group Voestalpine Schienen GmbH presented an interactive life-cycle cost tool for railways in the region at the recently-concluded Middle East Rail 2017.

The tool enables infrastructure managers to evaluate various rail-related procurement and maintenance strategies as well as to determine costs over the entire life cycle (LCC) of the tracks in a railway project. The system allows users to select a variety of parameters, including the type of operation, track radius, load and the rail grinding regime, as well as the rate of metal removal to determine the ideal solution in terms of cost over the life of the track.

Lukas Prettner from Voestalpine Schienen’s product management, said: “Ultimately, longest possible service lives combined with lowest maintenance necessities lead to maximum customer benefit from an economical point of view. This is a well-known fact as depreciation costs in infrastructure usually represent the majority of the costs, which decreases enormously by longer component service lives. The grinding costs are also a relevant parameter that can be positively influenced by choosing highly resistant rail materials, finally lowering the costs for rail maintenance.”

While the Middle East’s environment is characterised by harsh conditions, such as desert landscapes and extreme temperatures, requiring the most resistant rail steels to resist rapid degradation, the system allows the factoring in of these conditions for users in the region, Prettner said.

Voestalpine also presented new rail steel grades, highly digitalised integrated rail system solutions, and a wide range of services at the show.

In the Middle East region, the company is supplying to the Doha Metro and has recently succeeded in winning orders in the short-distance traffic sector for over 800 turnouts including transmission systems. It is also supplying more than 26,000t of sophisticated high-quality rails for what is currently the world’s largest metro project in Riyadh, together with the corresponding turnout and transmission technology, Voestalpine revealed.

The company also said it has received two major orders to develop and supply high-tech monitoring systems in Germany and Austria, and is playing a key role in extending China’s high-speed rail network as a specialist for high-speed turnouts. Already the longest network in the world, by 2025 it will have been extended to around 38,000km, roughly twice its current length. Voestalpine is delivering around 300 special turnouts a year designed for speeds of up to 350 km/h for the Chinese railways system, the company added.

In the short-distance traffic sector, the company has also won other important contracts in Asia to supply special turnouts for construction of the rapid transit railways in Kuala Lumpur, Malaysia, and for the metros in Bangkok and Ho Chi Min City.