Scania is celebrating the 100th birthday of its foundry in the company’s headquarters in Sweden. This facility in Södertälje is where the heart of a Scania vehicle is created: the cylinder block and cylinder head.

Over a century since its establishment, the foundry has seen several changes. From a heavy reliance on craftsmanship, the process today has become highly mechanised.

”The operation has a long history, but our focus has always been on quality, tensile strength and the working environment,” says Kent Wargclou, a former head of the Scania foundry who has spent 42 years working in the facility.

Fredrik Wilberfors, Design Engineer at Scania R&D, says quality control is an important part of building engines at the facilty.

“The largest advantage of having our own foundry is that we can control the quality in all steps of the production process, right from the beginning with the casting of the part until machining and the final assembly of the engine,” Wilberfors says.

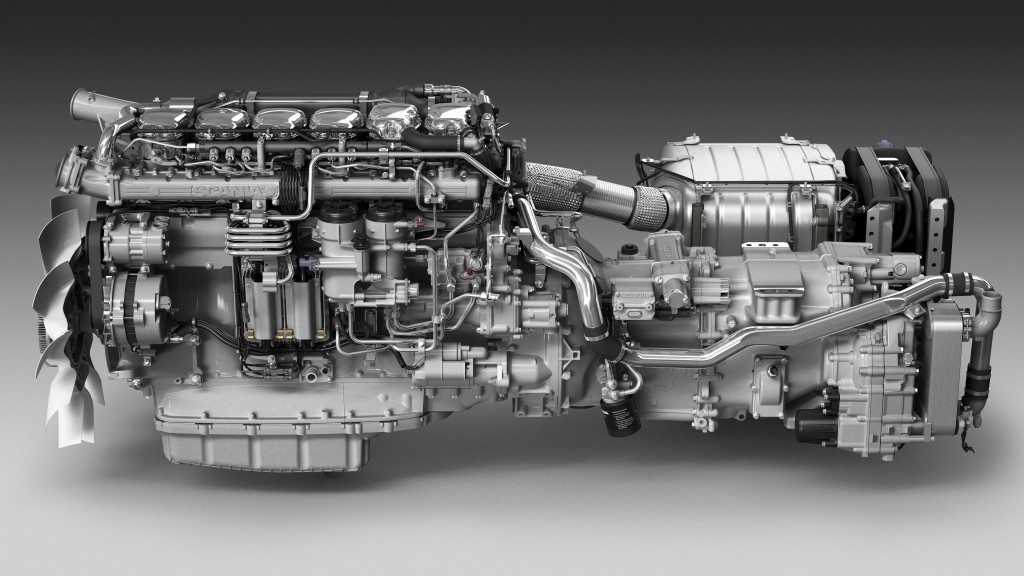

The Swedish firm produces somewhere between 85,000 and 90,000 engines annually. These are then fitted in trucks, buses, boats, or used in industrial machinery, after which they are delivered to customers the world over. And most begin their journey at the Scania foundry in Södertälje, Sweden.