Raj Stones has a crush on Sandvik

New Sandvik cone crusher improves Raj Stones’ output

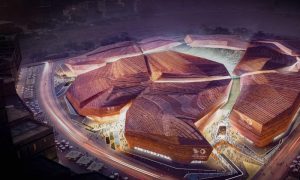

Raj Stones, a quarry based in Fujairah, UAE, has seen its aggregates production increase through the use of a CH660 cone crusher, built by Sandvik Construction.

Raj Stones, which began operations in 2004, expanded with the acquisition of another quarry named Raj Rocks LLC in 2008, and in a short time has developed a highly successful operation, supplying for the construction industry in the UAE, Qatar, and wider region.

Owned by Raj Group, the Group produces in excess of 8 million tonnes each year of high quality gabbro aggregates, as well as rock products for asphalt and ready mix plants. Across its two quarries it has total estimated mineral deposits of 265 million tonnes and both quarries possess multi-stage crushing lines.

In order to modernise their production capabilities, Raj Stone purchased Sandvik CH660 cone crusher, capable of producing aggregate to the required specifications at a throughput of between 450-500mtph. The new cone crusher would replace their existing Sandvik-supplied H6800.

With hydraulically adjusted CSS, optional automation, a choice of several different crushing chambers, and many other high performance features, each model is versatile, user friendly and highly productive.

The CH660 has proved to be ideal for Raj Stones’ secondary requirements because of the new design of the intake flow. Other features are its automatic overload protection, and the automatic setting system, ASRi.

ASRi optimises cone crusher efficiency by automatically adapting the crusher to variations in feed conditions, and by continuously measuring and compensating for crusher liner wear the it allows the user to fully utilize crusher liners, thereby scheduling liner replacements in order to coincide with planned maintenance.

The ASRi also assists in keeping the crusher choke fed, thus maximising rock-on-rock crushing, which helps to optimize the quality of the final product.

A combination of Constant Liner Performance (CLP) crushing chambers and high motor power, gives the crushers very high capacity. Nevertheless, the Sandvik CH660 design as used by Raj Stones has undergone an extensive upgrade designed to optimize operations at all levels, with these enhancements covering the entire crusher, including the feed hopper, top shell, bottom shell and main shaft/ head center.