Redcon Construction: Revolutionising reinforced concrete detailing and shop drawing production

Unlocking efficiency with 60% of saved time

Commitment to excellence

Redcon Construction has been a driving force in Egypt’s modernisation for decades, leaving its mark with towering skyscrapers and innovative construction projects that redefine the country’s skyline. As a leader in the Engineering, Procurement, and Construction (EPC) industry, Redcon has always upheld a commitment to delivering excellence to its clientele. Much of the company’s success lies in its unrelenting drive to find new solutions that increase productivity, maximise workforce capacity, and ensure lasting success for its clients.

Navigating 2D Obstacles

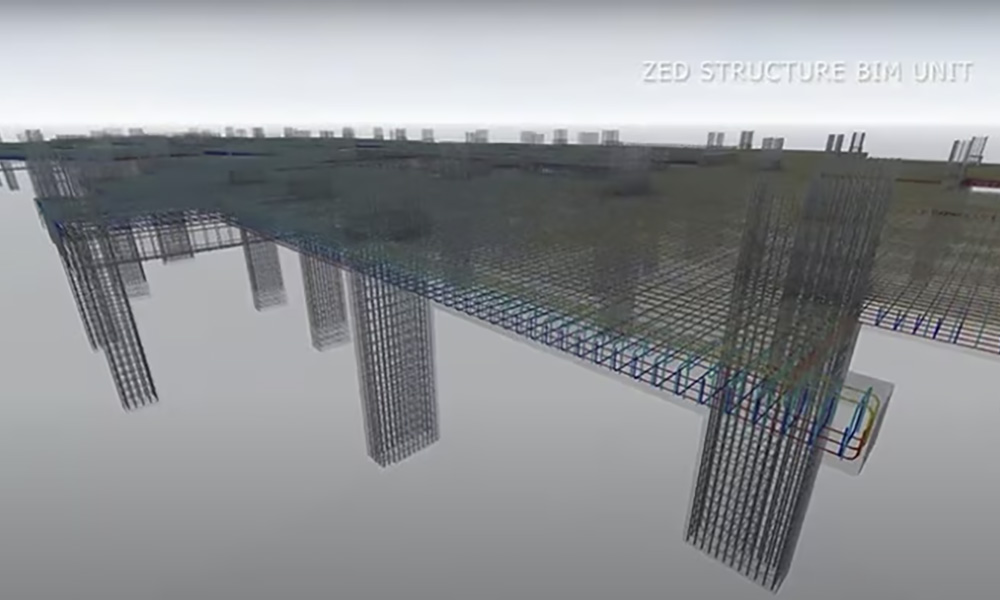

Before the adoption of BIM, the construction industry relied heavily on 2D methodologies for reinforced concrete (RC) design and detailing, which presented its own set of challenges that hindered progress and efficiency. Redcon’s engineers experienced this first-hand in the ZED Towers Project, a mixed-use commercial and residential tower development consisting of two distinct phases, Phase 1 and Phase 2.

During Phase 1 of the project, the structural team faced significant challenges due to their reliance on 2D drawings. These challenges included difficulties in coordinating with other disciplines and adapting to frequent design changes. This reliance also extended to Reinforced Concrete shop drawing production. Translating complex structural shapes and details into 2D plans and sections proved challenges, often resulting in inaccuracies and additional work. Additionally, creating accurate Bar Bending Schedules (BBS) for each element in a 2D software environment was time-consuming and error-prone. Furthermore, automating rebar splices, a critical aspect of reinforced concrete design, was challenging within the constraints of 2D, further complicating the workflow. Such errors had a significant impact on both project timelines and material consumption.

Moreover, precision was often compromised in the 2D environment, leading to costly rework and delays as errors were only identified during construction. “Keeping up with changes in the 2D environment (drawings) was challenging. Each time changes occurred, we had to rebuild the drawing, even when the site had already received the revised drawings and initiated work. Drawing in 2D posed difficulties in obtaining accurate measurements, as we could only draw using variable lengths.” said Mohamed Shabaan, Redcon’s Technical Office Team Leader.

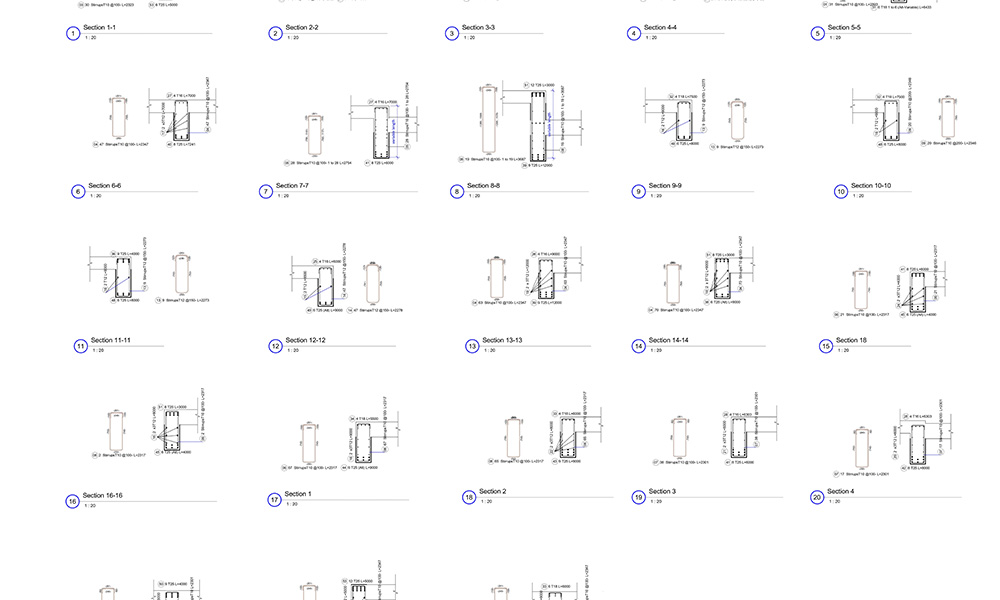

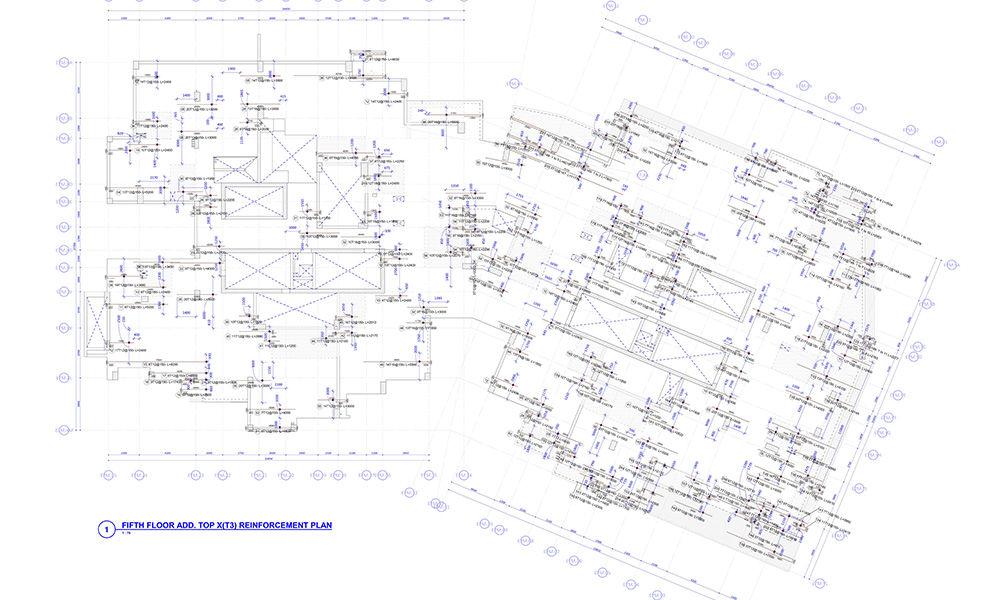

Drawing Extracts

Shop drawing 1 extracted from Revit

Shop drawing 2 extracted from Revit

Shop drawing 3 extracted from Revit

Paving the way for collaborative synergy and enhanced productivity

Redcon recognised the need for a solution and decided to use Autodesk Revit, leading to a revolutionary change in how they approached reinforced concrete design and detailing. With some custom features added by the R&D team, Revit 2020 allowed Redcon to create 3D models that provided a transparent, detailed, and interactive representation of their projects. This improved understanding and decision-making among project stakeholders and reduced waste. This was critical for Redcon as waste increased over the 5% standard rate. “ The primary reason for adopting BIM software was to minimise rebar wastage” Mohamed further explains. “We soon noticed that reducing waste led to increased team productivity.”

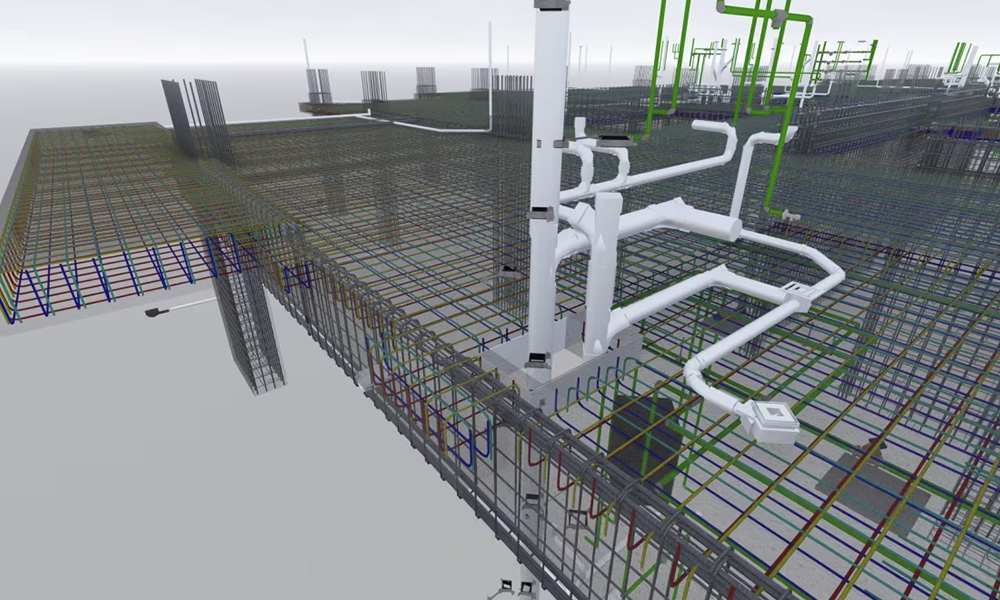

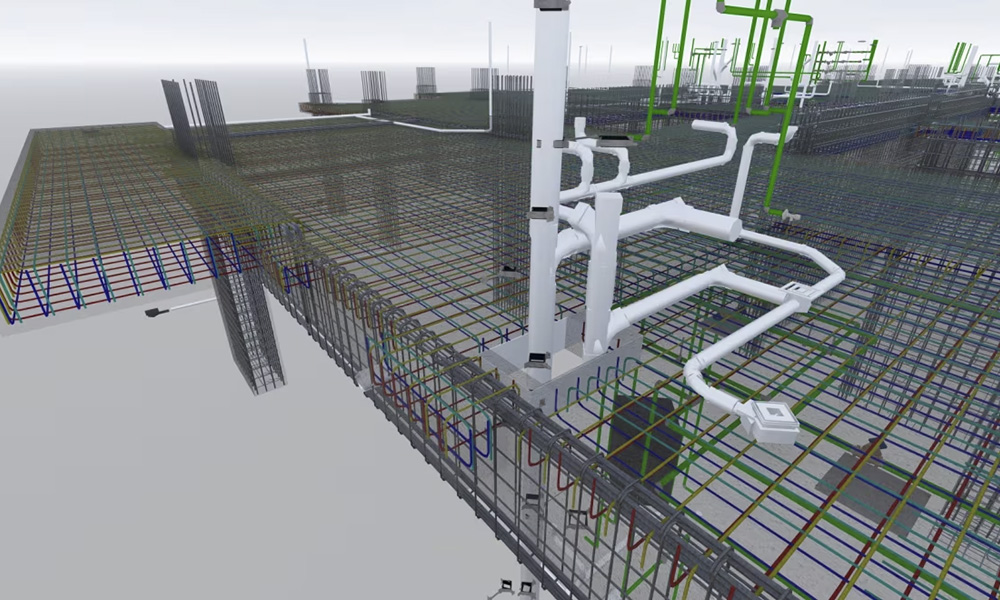

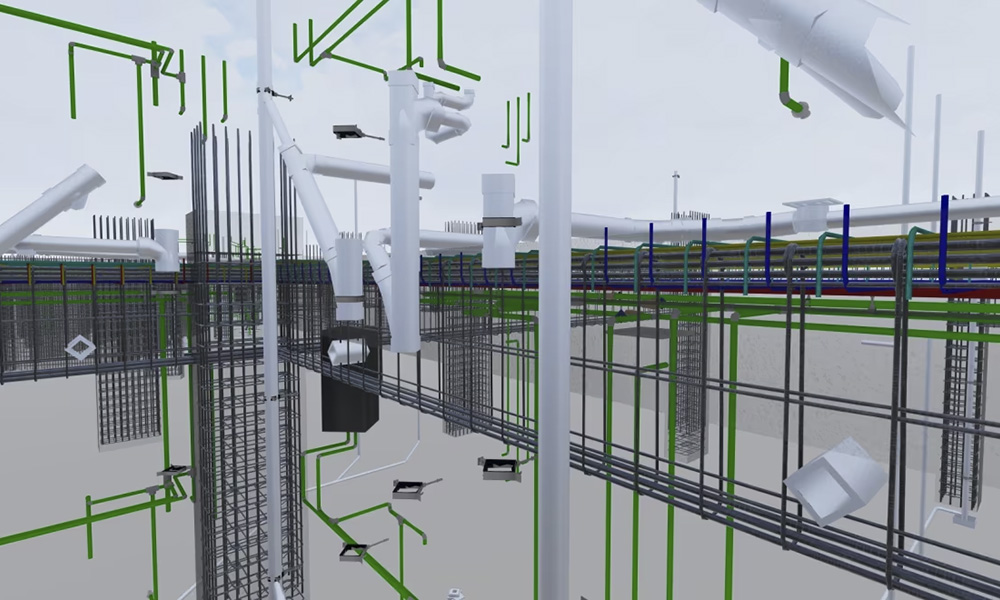

Coordination model: MEP, reinforced concrete openings, and 3D reinforcement

The Use Of Revit

The use of Revit has also improved measurement accuracy, allowing engineers to create comprehensive Bar Bending Schedules (BBS) and sophisticated rebar models for complex structural elements. Notably, the representation of reinforcement in 3D, which was initially challenging in 2D, has resulted in precise length calculations, providing engineers with more accurate quantity takeoff for reinforcement materials. This enhanced accuracy has significantly reduced rebar wastage, ultimately lowering overall costs.

Moreover, BIM has streamlined real-time coordination among architects, engineers, and construction teams by offering a centralised platform for efficient collaboration. With real-time updates and cloud-based accessibility using Autodesk BIM Collaborate Pro, all stakeholders work with the most current information. This flexibility has enabled Redcon to make design updates seamlessly, ensuring a smooth and efficient design process and assisting in meeting stringent project schedules.

Clash Free Rebar Modeling

Rendered Models

ZED Project Redcon Scope

ZED Structure Models Rendered

Rebar Modeling Clash Free Model

Efficiency In Numbers

In Phase 1 of the project, seven structural engineers completed 1,535 sheets of concrete and reinforced concrete shop drawings over 12 months. In Phase 2, where BIM was implemented, the project involved only five engineers, who generated 4,250 sheets within the same period. Farag el-Saadany, Senior Engineer, estimates that BIM reduced overall modeling and annotation time by 50% to 60%, significantly cutting shop drawing time and enabling early clash detection. This remarkable improvement reduced the required workforce by 29% and nearly tripled the productivity of structural engineers, while minimising human errors throughout the workflow, from modeling to extraction. According to Mohamed ElSarha, R&D Manager, the new features for reinforcement detailing and show drawing in Revit 2024 will allow 50% to 60% performance and efficiency boost.

Maximising efficiencies through digital adoption

Redcon’s commitment to integrating Revit into its projects, supported by top management, reflects their proactive approach to embracing technology. “Our Chairman always says this: Technology pays off. Implement it today, and it will reward you in the future.” said Mohamed El Sarha.

Providing insight into the company’s digital adoption strategy, Ahmed Ibrahim says, “BIM is deeply integrated into Redcon’s corporate culture, reaching beyond technical departments to ensure seamless information integration, enhanced security, and accessibility for all stakeholders.” This strategic adoption of BIM positions Redcon as a construction leader in the Middle East region, showcasing the transformative power of technology in the industry.