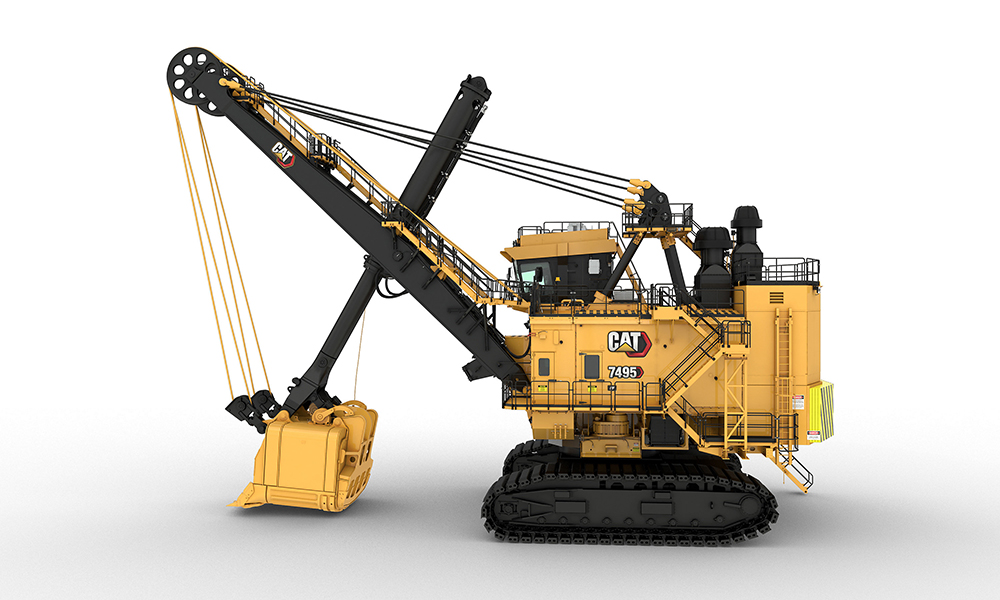

Caterpillar has upgraded its 7495 and 7495 HF Electric Rope Shovels (ERS), with the 2021 models combining multiple new standard feature improvements to increase operating efficiency up to 10% reduce cost per ton of material moved by as much as 15%.

A statement from Cat said the improvements had been brought about by component enhancements, increased frame durability and enhanced serviceability, all of which the company drew from more than a century of rope shovel innovation.

Dan Wyatt, ERS product value stream manager at Cat, said: “Consistently, our customers tell us machine availability and productivity are primary contributors to their operation’s success. From the full adaptive control system for HydraCrowd™ to more innovative technology and data security, the advances made to the 2021 electric rope shovels reflect our commitment to meeting their needs. Many of these improvements are compatible with shovels in the field, so customers can realise these gains through upgrades to their existing fleets as well as new machine purchases.”

According to Cat, a new propel gear case for the 7495 and 7495 HF models nearly doubles the life of propel gear cases in some extreme operating conditions. Precise adjustments to gearing geometry and advancements in tooth hardening enhance gear case durability and productivity. The result is lower total cost of ownership as much as $8 per hour when the drive system is replaced at one scheduled time. Additionally, an ecology drain simplifies oil draining and enables kidney-loop flushing, which reduces abrasion-causing contaminants and oil change frequency.

Updates to the 7495 AC electric drive system deliver greater reliability, improved maintenance access, enhanced safety, and expanded high-altitude and temperature capabilities. A liquid-cooled motion regulator cabinet efficiently dissipates heat generated by electrical components and enables operation at 50 degrees Celsius and altitudes as high as 5,250m without derating. A faster propel transfer switch cuts lag time by 75% to improve productivity, while common motors in multiple applications means fewer parts to stock, improved parts availability and simplified maintenance.

Slashing maintenance time by days while enhancing safety, reconfiguration of the crawler carriage allows drive shaft and tumbler replacement from the outboard side without removing the propel transmission. With this design, thrust loads are evenly distributed on large, tapered roller bearings rather than bronze thrust plates, increasing durability to align with 25,000-hour planned rebuilds, even in harsh environments.

Both the 7495 and 7495 HF come standard with Cat’s Product Link Elite, which transmits critical machine operating data such as utilisation, location and condition via cellular or site internet connection. Added router functionality helps to protect data security. Advanced productivity tools within Product Link Elite enable a cycle segmentation algorithm, and the combined data allows for advanced analysis of productivity.

When linked with the available Cat MineStar™ Fleet, real-time machine tracking produces a comprehensive overview of all equipment assets to assist with fleet management and productivity. Providing real-time feedback to improve loading efficiency, available MineStar Terrain uses guidance technology and an in-cab display to deliver precise dipper position guidance. Optional MineStar Health delivers critical event-based machine condition and operating data, while its advanced diagnostic and analytic tools improve service efficiency.